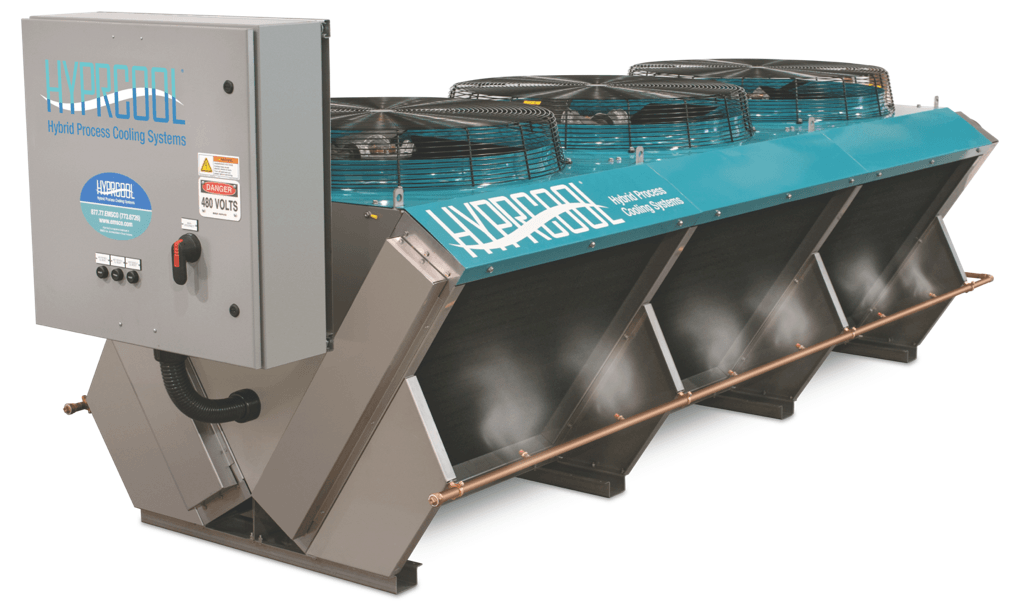

HyprCool® Hybrid Process Cooling Systems

Advance Your Process Cooling Technology

HyprCool® Hybrid Process Cooling Systems save customers tens of thousands of dollars in water treatment chemicals each year and reduce cooling system water consumption by up to 90 percent using adiabatic cooling technology. HyprCool systems wipe out one of the primary breeding grounds for Legionella bacteria, eliminate seasonal freezing and overheating issues, and are virtually maintenance free.

HyprCool increases efficiency in these key areas:

Energy

Energy

HyprCool fans turn on in stages and only run when required to maintain the desired operating fluid temperature. NEMA Premium Efficiency Motors are used in compliance with the Energy Independence and Security Act of 2007.

Water

Water

The HyprCool hybrid adiabatic system uses a fine spray of water only during the hottest months of the year when process fluid and ambient air temperatures dictate.

Health

Health

HyprCool eliminates the standing water found in evaporative cooling towers – thus eliminating one of the primary breeding grounds for Legionella pneumophila – the bacteria that causes Legionnaires’ disease.

Space

Space

Square footage is a premium in most foundries and industrial facilities. HyprCool features a significantly smaller footprint than traditional dry coolers.

HyprCool systems are custom manufactured by our sister company, EMSCO, at its engineering and production facility in Alabama, U.S.A.